Groundwater level monitoring: Not as simple as it seems (2 of 3)

This is the second of three articles where we share some commonly overlooked issues that could impair your water level data and subsequent assessments – this time we’re looking at water level dippers. In other articles we’ll explore your choice of datum and look at other factors which may influence your results.

Water level monitoring is a doddle, right? Chuck one of those water level dipper tapes down a monitoring well until it goes “beep” and note the depth it says at the surface? Well, not really – in these days of millimetre accurate topographical surveys, we really should be able to consistently, precisely and accurately measure the depth to groundwater at a site.

Water level monitoring: Is your equipment up to the job?

Having established the datum to measure from, we now need to ensure that the measuring equipment is reliable and accurate. From our extensive combined experience of monitoring with water level dippers over the years, Soilutions suggest that the following should always be considered either as part of yearly maintenance, or as part of every monitoring visit.

Stretching

The measuring tape component of water level dippers can stretch over time. We have noticed this more with cheaper models and for longer (and thus heavier) tapes. Stretching will affect accuracy and is likely to impact deeper wells to a greater degree. Use of different dippers over multiple monitoring rounds will also impact precision where one or more tapes have stretched.

Verticality

The tape and water probe must hang vertically within the monitoring well for depth measurements to be precise and accurate. We have found that taking care to respool the tape back on the dipper prevents kinks and folds in the tape which will influence verticality. The connection between the tape and the probe can also be a weak point and cause for the probe to hang at an angle. Again, we find that correct storage by ensuring the probe is placed in the supplied holster between uses minimises this issue.

Kinks and knots

If you’ve got knots in your measuring tape then you really should be re-examining your monitoring protocols! Kinks and twists on the other hand can be quite common, but easily avoided if care is taken when respooling the tape back onto the dipper reel.

Repairs and length changes

It’s a fact of life that dipper tapes are subject to nick’s and cuts which can break the electrical connection to the probe and renders them useless. Repairs typically involve the need to remove a small section of tape, re-establish the electrical connections and then waterproof the repair. Such repairs will obviously change the tape length and impact any measurement of water deeper than the repair point. Even when removing a full 1m of tape (to allow cm and mm elements to be correct) an experienced field technician can still forget to deduct that metre from the measurement. Ideally the whole tape or dipper should be replaced to remove this chance of error.

Flat battery

There is nothing worse than travelling to a site for groundwater monitoring only to find your water level dipper is not working. Whilst this may be due to a broken tape (see above), another common cause is a simple flat battery – depending on the remoteness of the site, this could waste hours to replace. At Soilutions, we have got in the good habit of

- Testing the dipper before leaving the office/storeroom (most have a test button, or use a cup of water);

- Carrying a spare battery in our tool kits (remember to keep it in a packet or with terminals taped over to prevent shorts); and

- Turning off the dipper after use and ensuring the probe is dry and correctly stored.

Dipper sensitivity

Dippers react differently to differences in groundwater, monitoring well moisture levels and condensation. A sensitivity dial is essential to enable the monitoring technician to be able to differentiate between the real depth to water and for example: moisture of the well sides at shallow depths (false-positive); or low conductivity groundwater (false-negative). The dial increases or decreases how sensitive the probe is to water and is present on all dippers used at Soilutions.

Buzzers and bulbs

The probe touching the water surface in a monitoring well is usually accompanied by a buzzer sounding and an LED lighting. It’s a good idea to have both since the LED might not be visible in bright sunlight and a buzzer may not be audible in a noisy environment.

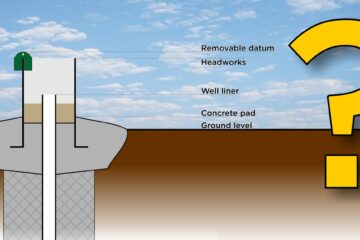

Friction

The continual lowering and raising of the dipper tape into and out of monitoring wells will invariably mean the tape rubs against headworks and well liners. Over time, this friction can wear away the depth markings on the tape and also expose the electrical wires within the tape. Soilutions suggest the use of good quality tapes and to always unspool and spool the tape with the reel directly over the centre of the well to prevent the tape being dragged across the lips of headworks etc.

Conclusion

Overwhelmingly from the above summary, it is clear that for quality results which are both precise and accurate, correct treatment of the water level dipper is paramount. They may well be able to continue working when maltreated in the field, never cleaned nor maintained – but some robust monitoring protocols and checks, combined with occasional TLC, should ensure your dipper continues to provide superior water level data for many years. Here at Soilutions, we have confidence with all stages of our data collection – including water level monitoring – so can rely on it as the basis for important assessments and decisions.

Leave a Reply